Cash Flow Myth 3 - Having Enough Capital

We have enough capital to not worry about Cash Flow. From the time this type of thinking starts to permeate the organization it is just a matter of time before there will be a cash flow crisis.

Cash Flow Myth 2 - Finance Manages Cash Flow

Finance people manage cash flow. The reality is that by the time the finance team gets involved in a cash flow problem there are very few levers they can pull.

Cash Flow Myth 1 - Profitability Does Not Equal Cash Flow

Cash flow does not equal profitability. While in theory these two critical scoreboard metrics are disconnected in reality cash flow is a pretty reliable predictor of profitability both good and bad.

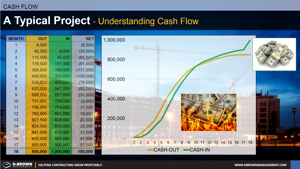

A Typical Project - Cash Flow S-Curve

Ensuring great financial outcomes is the ONLY way to build a sustainable construction business that can serve customers and develop team members over the long-term.

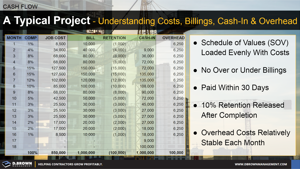

A Typical Project - Understanding the Basics of Cash Flow

Previously we looked at a typical construction project's profitability basics and covered a brief description of cash flow. Now let’s get into the basics of how that looks over the course of the project with a simple model of a 16 month project.

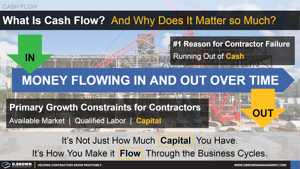

Cash Flow Explained

Contractors run on very thin profit margins however cash flow is even more important for sustainable growth. Poor cash flow is a primary reason for contractors failing or their profitable growth being seriously constrained.

A Typical Project - Project Profitability and Understanding the Basics

It is crucial for everyone in a construction company to understand the financial basics of a project. Contractors have razor-thin profits and relatively high risk.

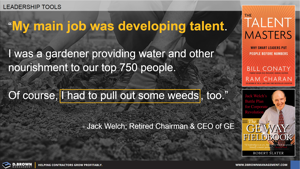

Talent Development Quote - Jack Welch

From 1981 through 2001 under CEO Jack Welch, GE’s market cap (value) grew 18% compounded annually from $14B to $410B. A large part of this profitable growth was due to the rigor placed on their talent development processes directly from the CEO.

TalentTalent - Sustainably Integrating the 4 Priorities

When assessing the strategic importance of investing in your talent acquisition and development processes at the field leadership level it is important to understand the depth of the talent shortage over time.

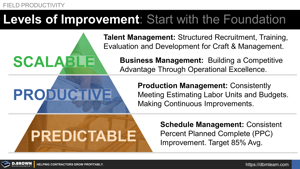

Levels of Improvement: Start with the Foundation

Every process in your business including field productivity will go through three levels of improvement: From predictable to productive to scalable. Trying to skip levels is the surest way to slow down improvements across the company.

business management labor productivity