Lean Principle - Stop Work (Until Problems Are Corrected)

All construction projects will run into some degree of problems. It is how the project team chooses to manage these problems that ultimately determines the outcome of the project.

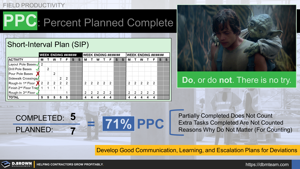

field productivity lean constructionPercent Planned Complete (PPC) - Calculation Example

Yoda would be the perfect coach for managing schedules on projects: “Do or do not. There is no try.” This is the heart of Percent Planned Complete (PPC) and the weekly cycle of continuous production improvement.

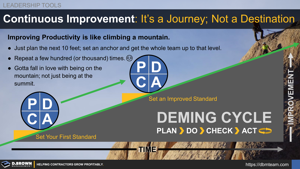

field productivity foreman training lean constructionContinuous Improvement: Plan, Do, Check, and Act (PDCA)

Improving productivity in construction is exceptionally challenging. It must be embraced as a journey and not a destination. It must be made into a game so that people clearly see what winning looks like and fall in love with the process.

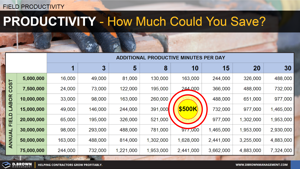

field productivity lean construction managementLabor Productivity - How Much Could You Save?

Winners of the construction labor productivity is a game focus on minutes and seconds looking at ways to eliminate waste. There are 480 minutes in an 8 hour shift. Typically only 307 of them are spent installing material. What are 10 minutes worth?

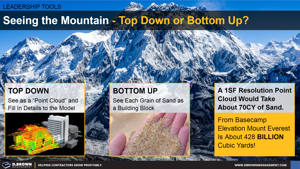

Seeing the Mountain - Levels of Detail

You will find a clear path to the top of the mountain faster as you build your ability to situationally vary the resolution you see the world in. This applies to the construction of a project, the building of a contracting business and to life in general.

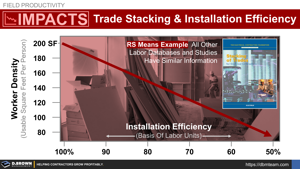

Impacted Productivity - Stacking of Trades and Installation Efficiency

Each craftsperson needs about 200 usable square feet for a productive installation. This assumption is included in production units used to estimate and budget projects. Having less than that can impact productivity up to 50%.

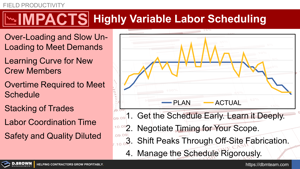

change management claims estimating field productivityImpacted Productivity - Highly variable Labor Scheduling (Level Your Schedule)

The biggest risk for a specialty contractor is the performance of on-site labor. One of the biggest impacts to labor productivity is having a schedule that requires large variations in labor.

change management claims estimating field productivityProduction Tracking - Don't Be a Dry Monkey

Put a few monkeys in a cage with a ladder that has bananas on top. One monkey immediately goes for the bananas. Cold water sprays on the others. Don't let anyone on your team be a dry monkey when it comes to production tracking or schedule management.

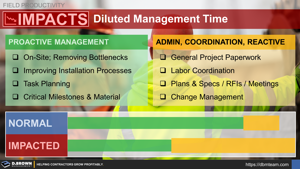

Impacted Productivity - Dilution of Management

Dilution of management will compound an already impacted construction project. It is important for teams to realize the full costs of impacts as they start to occur.

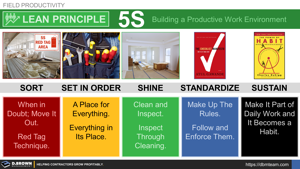

change management claims field productivityLean Principle - 5S Habits for Building a Productive Work Environment

5S is a foundational concept for creating a productive work environment and continuous improvement. The 5S process is to productivity what eating a healthy breakfast and exercising is to your health - daily consistency will change your life.

field productivity lean construction