Building an effective project team across dozens of different companies with sometimes competing interest is incredibly difficult.

These are daily struggles that leaders and everyone on the team must navigate and LOVE.

Is there a faster way? A shortcut? An EASY BUTTON?

How did they (reference someone else) get there so fast?

It’s easy to get caught up asking ourselves these questions too much or worse yet by blaming others on the team including leadership for things being so difficult.

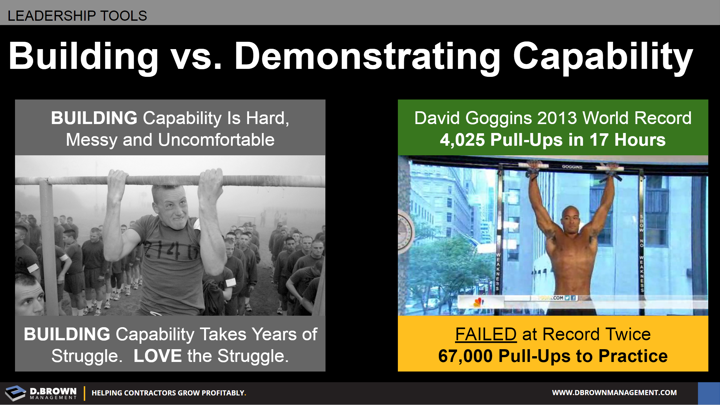

The elements we see publicly of others are usually either big problems or the demonstration of a capability that has already been built after years of struggle. When these are put together in media formats such as The Profit or Shark Tank we can begin to think we can go from major problem to solution in 30 minutes!

Assume that about 95% of your time will be the struggle to build capability whether it is in business or life and whether it is mental, physical or financial.

Consider David Goggins and his pull-up record from 2013. The first couple thousand looked pretty easy (for him) but what we don’t see publicly was the YEARS of training it took to get there including several failed attempts.