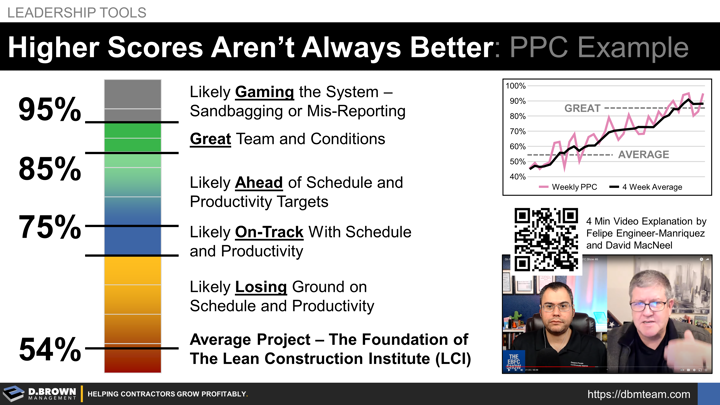

Percent Planned Complete (PPC) is a critical measure of a weekly work plan or SIP (Short-Interval Plan).

David MacNeel from On Point Lean describes that higher scores aren't always better in this interview with Felipe Engineer-Manriquez on the EBFC (Easier, Better, for Construction) Show (4 minutes starting at 0:20:00)

54% was the average amount of weekly tasks that got completed as planned when Greg Howell and Glenn Ballard first studied the problem in the late 90s.

Low to Mid 70s: Likely on-track with schedule and productivity (Two Key Results for Project Planning)

High 70s to High 80s: Likely ahead of schedule and productivity targets.

High 80s to Low 90s: Great team and conditions.

Mid to High 90s: Likely gaming the system - sandbagging or misreporting.

An important part of your scorekeeping process is setting appropriate targets with tolerances and clear management escalations if there are large variances, or they are trending in the wrong direction for too long.