It is how the management team chooses to manage these problems that ultimately determines the outcome of the project.

The tenacity to keep moving forward, no matter what, is an amazing trait shared by many in construction. It is what moves projects forward. It is also the trait that will get project teams in massive trouble when the problems reach a tipping point that makes their plan unworkable.

There is a line of reasoning that says moving forward and continuing to work is what must be done. There is even contract language including liquidated damages that can reinforce this mentality.

The automobile industry had the same mentality:

“Never stop the production line - no matter what. It costs thousands of dollars per minute.”

Toyota, who is the world’s largest automobile manufacturer, looks at it differently:

“Quality and production are too important. We MUST stop the production line if we are struggling or have a quality failure in any way. That is how we troubleshoot, learn, and improve.”

Through their Andon system, they empowered everyone to stop production.

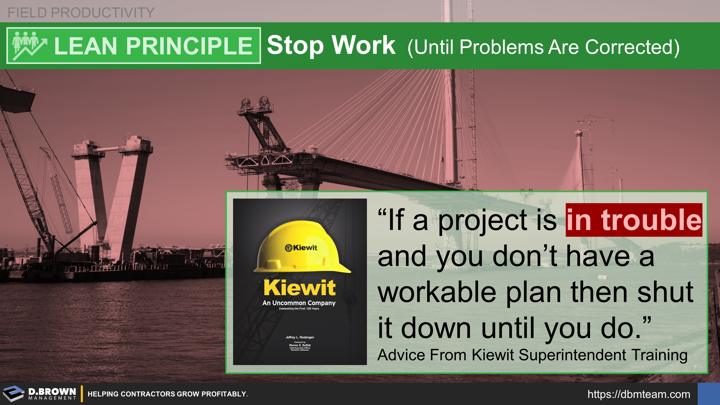

It’s a paradigm shift that some of the best and largest contractors like Kiewit have adopted.

“If a project is in trouble and you don’t have a workable plan then shut it down until you do.” - Advice From Kiewit Superintendent Training

Andon and similar policies are to productivity what Stop Work Authority (SWA) is to safety. Many of the adoption challenges are similar including:

- Culture

- Training

- Systems Including Notification, Investigation, and Follow-Through

Safety and SWA has some advantages in adoption over production policies:

- Easier to align the team around going home safely to their families each day.

- Standard measurements such as incident rates.

- Direct link to financial impacts with loss ratios and insurance rate modifiers.

- Reporting and SWA enforced by regulation.