During the last 20 years the construction industry has been rapidly adopting some of these tools to improve productivity.

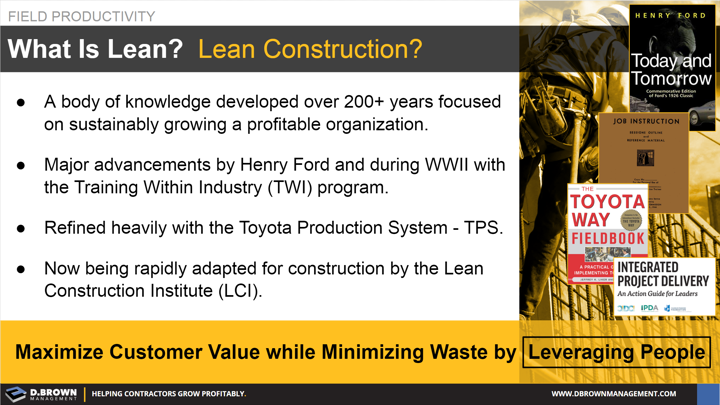

Major advancements were made by Henry Ford and during WWII with the Training Within Industry (TWI) program.

Toyota made major contributions to the body of knowledge from 1948-1975.

The term “lean” was only coined 30 years ago in 1988 by John Krafcik with Greg Howell and Glen Ballard starting to apply the concepts to construction around 1995.

The core concept of lean is maximizing customer value by minimizing waste and leveraging people.

The book Lean for Dummies elegantly defines value-add to the customer as having to meet 3 criteria:

- The customer must be willing to pay for it.

- It must transform the raw materials (inputs) in some way.

- It must be done correctly the first time.