Making improvements to field productivity requires a deep understanding of the entire value stream and the tools to effectively streamline it.

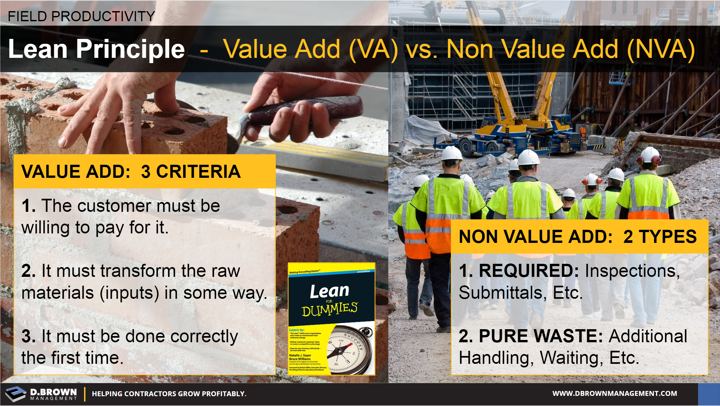

This starts with mapping out every step in the process then identifying those steps that are truly adding value to the customer:

- The customer must be willing to pay for it.

2. It must transform the raw materials (inputs) in some way.

3. It must be done correctly the first time.

When you look at each step through this lens you start to see a lot of activities that don’t add value (Non Value Add). These get broken down into two categories:

- REQUIRED: Inspections, Submittals, Etc.

2. PURE WASTE: Additional Handling, Waiting, Etc.

Our approach is “High-Involvement Workflow Mapping” which forces teams to slow down enough to truly see what they are doing, communicate with each other and identify then eliminate waste with each cycle (PDCA).

Helpful Resources

- Mike Brunner does a great job with 1:1 personal lean coaching that truly accelerates personal development.

- Lean for Dummies is a very well written book providing an overview of many lean concepts and history. Mike Brunner leverages this as part of his 1:1 coaching program.