The only way to keep up is to become experts at accelerating the development of teams.

Training construction teams to learn, teach, prioritize then act is something we have been working relentlessly on since 2005. It is one of six key strategies that we see contractors must execute to deal with the talent shortage that will become 3X worse in the next few years.

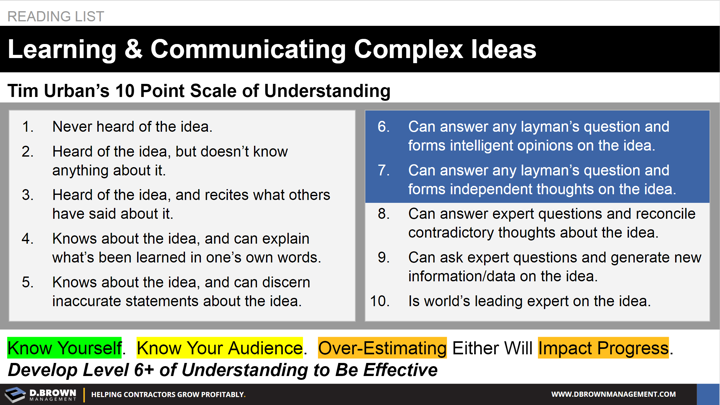

The other day this article was sent to us by Tim Harris who works with several of our clients helping them shape their recruitment marketing strategies. In the article Tim Urban discusses his process for learning and communicating complex ideas.

Tim’s scale of understanding (1-10) is an excellent way to even begin to understand what we know and what we don’t know. One of the problems with social media and the speed which we all run today is that there is very little focus on the deep understanding of a topic. We tend to believe that if you can’t make a complex idea simple enough to fit into a few hundred words then that is a failure. If only the world were that simple…

What if you looked at your job roles and rated your team on on this 1-10 scale?

Where are the gaps?

How can you close them rapidly?