There are many large changes on the horizon from more integrated project delivery methods to construction technology to the increased M&A activity in the industry. All being compounded by labor shortages over the next 15 years.

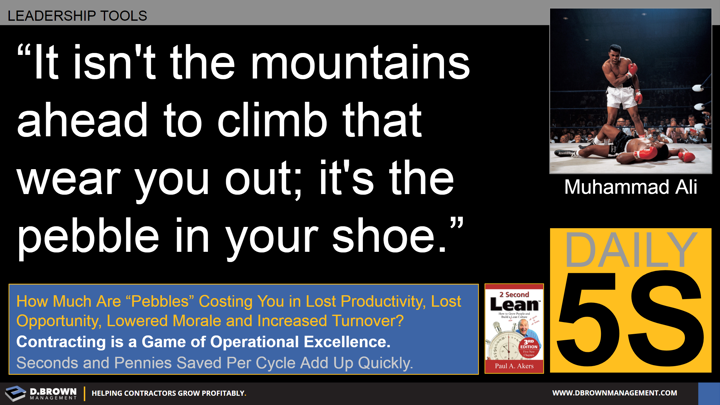

Between all these massive changes going on and the fires of daily operations it is easy for leaders and their teams to overlook the small opportunities for improvement every day.

Construction is a very labor-intensive business with many tasks being repeated anywhere from 10-100+ cycles per day. Saving just a few seconds per cycle adds up to huge savings over the course of a few years if you make it part of the culture - a daily habit.

Also consider the morale impact of people having to fight many small battles every day. Think about going on a hike up a tough mountain. Now think about doing this same hike with swarms of mosquitoes around you the whole time.

In the lean body of knowledge the 5S process creates these habits.

The book 2 Second Lean does a great job describing how to create this culture. It’s a very quick read and available in both English and Spanish with quantity discounts.