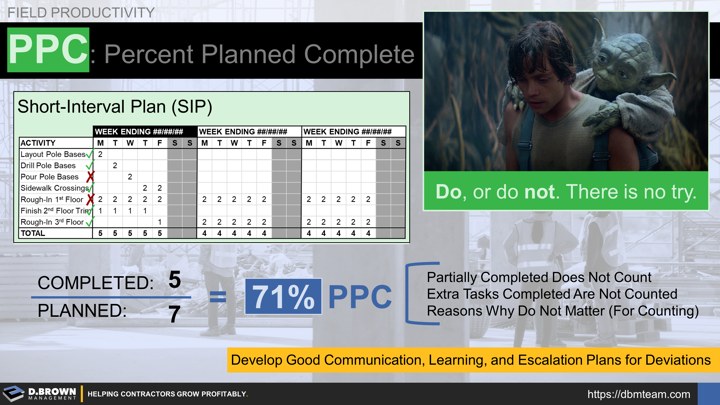

This is the heart of Percent Planned Complete (PPC) and the weekly cycle of continuous production improvement. Measurement of PPC is rigorous:

- Partially complete tasks DO NOT count.

- Extra tasks (not planned) DO NOT count.

- Reasons why DO NOT matter except for the weekly learning aspect.

Imagine designing a field supervisor coaching program with PPC at the center.

For 12 weeks, an experienced coach would work hands-on with a Foreman starting with a review of their PPC from the prior week and then developing the next week’s Short-Interval-Plan (SIP), focusing on:

This coaching will improve the Foreman’s capability to execute their key responsibilities and achieve their key results.