If a contractor doesn’t have a solid market strategy and organizational structure in place it’s very difficult to build a consistent backlog.

For construction leaders this is not a problem to solve but rather a paradox to manage rigorously through iterative improvement cycles.

- Assess your market strategy and refine. This is the most highly leveraged decision you will make. Get plenty of input to help you see different perspectives but once you decide then act relentlessly.

- Look at your organizational structure and determine what will best support your strategy.

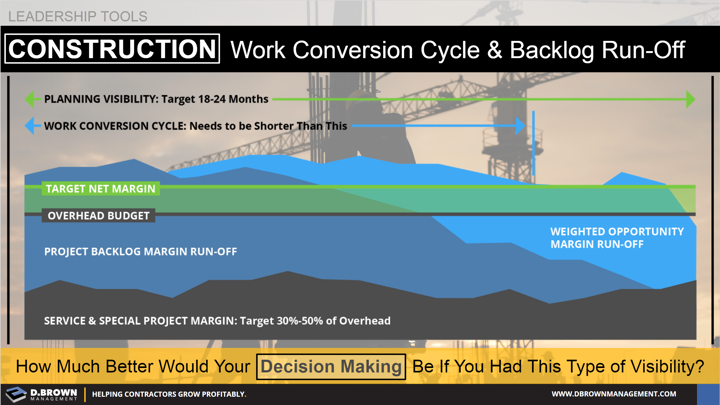

- Create a scoreboard around your backlog similar to the one shown that includes existing work, a foundation (if applicable) of service & special projects and a methodology of forecasting your pipeline.

- Develop a cascading set of objectives and key results that support your market strategy along with the lead measures you can manage weekly.

- Execute as if your company depends on it - it does. Go back to #1 to revisit at least annually.

Do your management systems including technology integration allow you to have this level of visibility?

Do you have a good mix of work with short, medium and long work conversion cycles?

Do you have a foundation of service and special project work?

Can you see out 12 months in advance? 18? 24? Set a goal and stretch. The longer out you can see the stronger your foundation for sustainable growth.