Those impacts can be positive or negative depending on how leaders and managers leverage the effect.

The IKEA Effect is a cognitive bias where people place disproportionately high value on things they helped create, even if the end product is lower in quality. Multiple experiments have been run to validate this in various situations and from the perspective of a seller and a buyer.

Depending on the situation and perspective, the person who helped create something valued it between 50% more and five times more.

E = Q x A

Effectiveness (Return) = Quality (of Idea) x Acceptance (by Team)

Frank Blake who is the retired CEO of Home Depot summarized this formula very succinctly. This is the first thing you have to keep in mind when it comes to leading and managing a team. This formula becomes exponentially more valuable as a contractor navigates different stages of growth and must prioritize improvements.

People place a higher value on things they help create. That sense of ownership drives acceptance and improves effectiveness.

- How many times have you watched the same problems occur over and over on projects?

- How many times have you purchased new software or tools and had them underutilized?

- How many times have you had a new procedure not get traction?

- How many times have you added a new role to the team and had the team fall short on integrating them?

- How many times have you set out to pursue a new market and had difficulty?

We have all had these problems to some degree.

One trait shared by effective leaders (right mountain, right direction) and effective managers (consistent outcomes) is the ability to engage people collaboratively and create alignment, without abdicating responsibility. It’s wisdom that dates back more than 2,500 years, long before the United States was formed and certainly before IKEA:

"A leader is best when people barely know he exists, when his work is done, his aim fulfilled, they will say: we did it ourselves." - Lao Tzu

The Dichotomy - Objective Quality Matters

Leaders and managers must balance this out to optimize the equation for the most effective outcomes.

If too much freedom is given beyond someone's capabilities, you both frustrate them lowering acceptance while also lowering quality. Effectiveness declines rapidly in this situation. It is one of the signs of a contractor at a growth inflection point.

Assuming you have the right leaders and managers in place, they will have the experience to make high-quality decisions very quickly. Akio Toyoda gives a great example of problem-solving capabilities ranging from 3 minutes to 3 months. For those highly experienced managers, they may be at 95% when it comes to the absolute quality of the decision but will fall short on both accountabilities of a manager:

- If they are managing a team of any size, they will fall short of delivering consistent outcomes because acceptance across the team will be lower. The manager will be in a position of constantly fighting fires due to that lack of adoption.

- If they are within a growing business, they will stunt growth because they are not developing others on their team. Their succession readiness and promotability will be low. This may also lead to higher turnover on their team as people see their career growth stunted. This makes recruiting people who are looking for career growth even more difficult compounding the situation.

The Balanced Skillset

Leaders and managers must have a combination of two skills:

- Knowing what to do - to make good decisions within the boundaries of their job role.

- The ability to engage the full range of people they must work with and through, meeting them where they are at, then stretching and aligning them.

The skills for the latter grow with importance as the job role progresses from front-line technical supervision through CEO. It also changes dramatically with headcount.

Application - From Strategic Alignment to SOPs

There are a lot of nuances to applying this with teams to both develop them and get higher levels of buy-in. Below are a few bullet point examples. Please contact us and we will share freely the many examples both good and not so good that we've seen.

- Separate out strategic brainstorming, strategic decision making, and strategic alignment processes. They are different and involve different groups of people. Ideas are not strategy. Plans are not strategy. More details about all six phases of the process here.

- Look at your 3-year business planning process similar to the phases of the strategy process. The business plan is about how you plan to allocate resources and prioritize actions over time to execute your strategy. This is one place where E = Q x A has the biggest impact.

- Engage a front-line person who is doing the task to write up the step-by-step procedure (Standard Operating Procedure / SOP). Company-level templates, guidelines, and storage locations should be provided from a higher level for consistency. Facilitate the person who built the first draft of the procedure cross-training someone else making continuous improvements for the first few cycles. This is a technique that goes back to the beginning of industrialization and was used extensively during WWII production where there were major talent shortages.

- Work with a team to map out entire cross-functional workflows. The Award-to-Start portion of the Project Value Stream (PVS) is one of the most valuable to map and refine for any contractor move towards stage 3 of growth or beyond.

- Whenever there are unexpected outcomes (way above expectations or way below), engage the team in a formal causal analysis process ending with prioritized actions, including refinement of SOPs.

- Engage multiple people in the hiring process - after they have been trained and with some structure.

- Pull-planning a project when done effectively is a perfect example of achieving commitment from those executing. Unfortunately, there are far too many ineffective pull-planning sessions being held - please don't judge the effectiveness of a technique based on the effectiveness of its execution.

- Study and practice techniques like the KJ Method / Affinity Map that help bring groups together.

Ownership Transition and Valuation

When it comes to ownership transitions, the IKEA Effect often naturally shows up. The seller, especially if they are the founder, will place a higher value on the business than a buyer. This does not make one of them right and one wrong - but it will keep a deal from being made if the two can't align.

- There is a wide range of Fair Market Value (FMV) for a construction business.

- There are seven basic drivers the create real value - focus on creating value, not just transactional value.

- The math of transaction has to work and that is largely a combination of forward-looking cash flow generated by the business, effective tax rates, and cost of financing.

- Ideally, you want the hand-off to be great for all parties - like Team USA 2024 Mixed 400M Relay World Record.

Guardrails and Scaffolding for Success

Remember that the higher levels of value placed on self-built IKEA furniture has to do with stretching someone's capabilities by providing them with everything they need. An experienced craftsperson benefits very little from the IKEA level of instructions and they probably aren't using the stamped wrench that came with the kit. The instructions and kitting aren't for them. They also don't detract from the process for that experienced craftsperson.

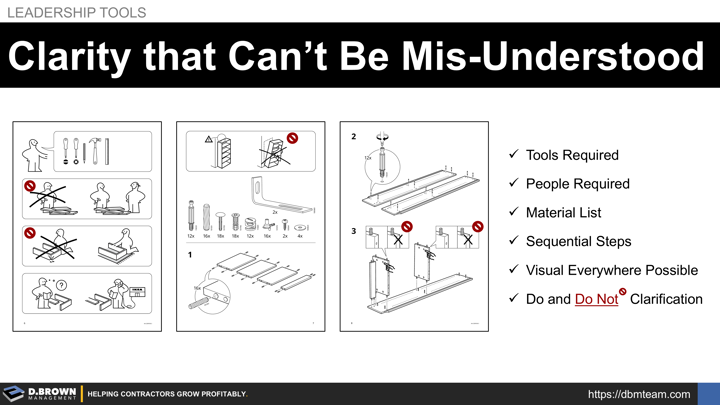

They are built with clarity that allows nearly everyone the joy of building something. The joy of learning different types of fasteners. That level of engineering discipline is what creates The IKEA Effect.

The role of leaders and managers is to take the concepts from the bullet points above and turn them into guardrails and scaffolding that are:

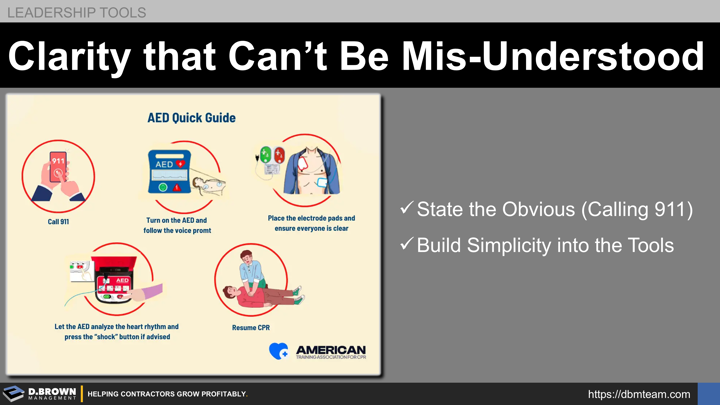

- So clear that everyone on the team can understand and use them - KISS. More importantly, so clear they are difficult to mis-understand.

- Leaving enough gaps so that everyone on the team is building it themselves and learning.

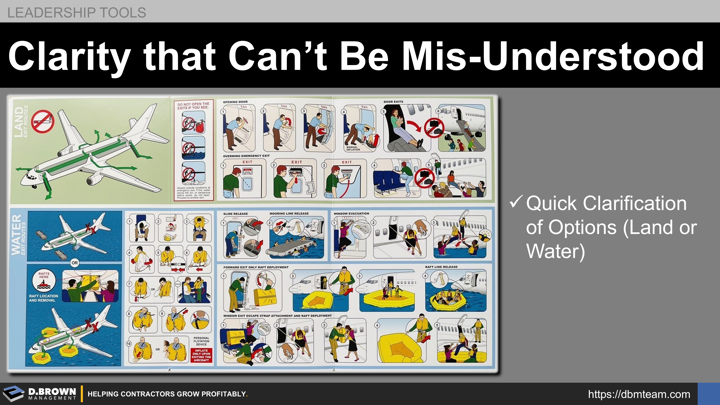

Below are a few examples from IKEA, airline evacuations, and heart defibrillators. Are your standards this clear?

Kitting, Prefab, Manufacturing, and Modularization in Construction

It goes without saying that there are tons of lessons to be learned from IKEA about how they engineer and flat pack their systems as it applies to contractors. That is way beyond the scope of this article and covered in many other places.

For interesting engineering, it is worth learning the history of Quonset Huts.